By driving the integration of the motor (including electronics) into the PCB itself, we’re facilitating the design of smaller, cheaper and faster applications.

- PCBMotor uses less space and material.

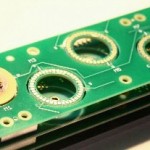

- Electronics (driver) and mechanics (motor) are mounted directly on the PCB – so it’s totally flat and without gears and connections.

- PCB enables more design flexibility – multiple motors can be mounted on one board.

- PCBMotor is a non-magnetic device.

- PCBMotor can generate more power and torque at a lower speed (without gears) than an electric motor of comparable size.

- PCBMotor has faster start/stop than electrical motors – giving more accuracy to the application.

We’ve actually a written a white paper highlighting the main differences between PCBMotor technology and Stepper motors. Sign up for free and discover:

- Major differences between stepper motors and PCBMotors

- Top 5 Pains electronic movement designers & engineers have

- Top 5 Gains you can achieve by employing a PCBMotor

- Motor performance results: Lifetime; Torque-Speed-Power; Torque Precision Correlation