How to Solve High Resolution and Low Speed Motion Control Dilemmas at a Lower Cost

We’re often asked, “How are our PCBMotors different from stepper motors?”

It’s an excellent question and why we wrote this white paper – How to Solve High Resolution and Low Speed Motion Control Dilemmas.

Sign up for this free white paper and discover the

- Major differences between stepper motors and PCBMotors

- Top 5 Pains electronic movement designers & engineers have

- Top 5 Gains you can achieve by employing a PCBMotor

- Motor performance results: Lifetime; Torque-Speed-Power; Torque Precision Correlation

Bonus Material free

Also included are the following offers at no extra cost:

- 30-Minute consulting service

- Six month money-back guarantee

- ‘Traveling wave’ patent information

Does Your Motion Control Application Require

- High resolution and holding torque?

- Lower production costs and bill of materials (BOM)?

- An improvement in the end-product’s look-and-feel, weight and height?

|

|

New Technology Beats Electromagnetic Motors

The table below gives application CTO’s, designers, and engineers a comparison of these two different motor technologies: stepper motors and PCBMotors.

DC & Stepper Motors

|

|

PCBMotors

|

Conventional electromagnetic motor using built-in step motor functionality for position control (open-loop motion control) Conventional electromagnetic motor using built-in step motor functionality for position control (open-loop motion control) |

|

Innovative piezoelectric motor technology for slackless movement in application (closed-loop only with position sensor) Innovative piezoelectric motor technology for slackless movement in application (closed-loop only with position sensor) |

- Require more application ‘real estate’

- Can’t be integrated on-board

- Require additional parts and mechanisms

- Have a higher bill of materials

- Aren’t conducive to thin, light applications

- Are constant power devices

- Lose torque with increasing resolution

|

|

- Offer compact design possibilities

- Integrate motors & drivers onto PCB

- Do not require clutches, gears & brakes

- Result in lower Bill of Materials

- Will lower application height

- Only utilize power in operation-mode

- Maintain full holding torque in power-off

- Are more energy efficient

- Offer more accurate angular positioning

|

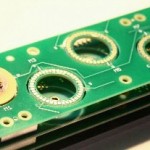

Demo the High Resolution Twin Motor Kit

If you’ve an application or product that you’re developing and would like to demo our rotary piezomotor to test it’s capabilities, the High Resolution Twin Motor kit is now available online in our shop.

|

|