…no more choppers, 4WDs & technicians in the field!

What are remote controlled tunable filters worth to you?Our customers increase the number of products sold to network carriers by being able to improve how filter frequencies are adjusted in the field.

They’re deploying filters that can be remotely reconfigured via a small, high precision motor so network carriers can more easily and cheaply maintain their networks, lower their operational costs and offer more flexible services.

THE CHALLENGE

Reconfiguring already-deployed filters to different frequencies is equally as expensive as the original deployment.

Are these issues relevant to you, and your company’s customers

- Costly, time-consuming field trips to remotely located areas?

- Increasing/expensive operating costs to maintain the network?

But wait, there’s more…

And, what if you could configure multiple filters remotely in a fraction of the time?

…with the possibility of:

- Final & automated tuning in the field

- Automated tuning in the factory

- Reducing the number of frequency variants

- Reducing the logistical cost of shipping the right filter to the right place

- Reducing inventory levels

THE SOLUTION

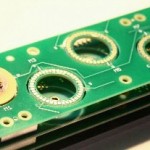

A remotely tunable filter solution is now available!With PCBMotor’s precision motor technology, your filters can be produced, deployed and (re-) adjusted faster than ever – both in the factory and remotely in the field – offering:

1. Possibility of changing frequency after deployment (remotely)

Remotely access each individual filter to change the frequencies.

2. Reconfigurable in the field

Once integrated, filter frequencies can be reconfigured in the field by technicians.

3. Automated factory adjustments

We’ve developed a fully-automated process that eliminates human involvement so filters can be pre-set to the required frequency during production

- Don’t need to install new hardware and send technicians into the field

- Can more efficiently manage more flexible, readily adaptive networks

Wouldn’t you like to be the person who transformed your customer’s network and lowered their operational costs?

IMAGES & VIDEO