About us

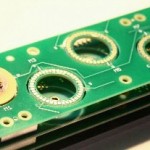

Our customers increase the number of products sold by being able to improve the (low) speed and (ultra high) resolution achievable in their motion control applications. They implement a small Piezo Motor directly onto a printed circuit board. This motor has a high resolution, hollow center, low weight and building height, off-power holding torque and, with it’s automated assembly process, lowers their Bill of Material.

PCBMotor’s core business model is to operate as a component supplier, delivering stator and driver circuits to low-volume solutions and Piezo components for higher volume.

To facilitate our customer’s time-to-market, our design services for Electronic Hardware & Firmware, Mechanical and Software solutions, enable fast and swift prototyping for complete motor solutions.

- GuidesRecentAll timeGuide how to: Deploy - Go to market

Guide how to: Develop - Fast prototype

Guide how to: Evaluate - learn and Turn

Guide How to: White Paper PCBMotor versus Stepper

Guide how to: Select size - Performance table

Guide how to: Reduce Motor Size by Integrating Accurate, Low Cost Piezo Motors

Guide how to: Design and layout

Guide how to: Solve High Resolution, Low Speed Motion Control Dilemmas at a Lower Cost

Guide how to: Build Applications with PCBMotor

Guide how to: How does PCBMotor's technology work?

What are the advantages of a PCBMotor compared to a stepper motor?

Popular Posts

How does PCBMotor’s technology work? (5,288)

How does PCBMotor’s technology work? (5,288) Video: 30mm diameter motor (100 sequences) (5,273)

Video: 30mm diameter motor (100 sequences) (5,273) PCBMotor v Stepper (3,857)

PCBMotor v Stepper (3,857) Whitepaper: How to Reduce Motor Size (2,929)

Whitepaper: How to Reduce Motor Size (2,929) Performance (2,437)

Performance (2,437) White Paper: Design Rules & Layout Guidelines (2,282)

White Paper: Design Rules & Layout Guidelines (2,282) White Paper: An Engineer’s Guide to Building… (2,208)

White Paper: An Engineer’s Guide to Building… (2,208) Introducing piezo motor technology (2,164)

Introducing piezo motor technology (2,164) Whitepaper: How To Solve High-Resolution And Low… (2,162)

Whitepaper: How To Solve High-Resolution And Low… (2,162) All our videos – here in one place (1,774)

All our videos – here in one place (1,774)